Aluminum Alloy Permanent Mould Process Gravity Die Casting

- Supply Ability:

- 50, 000 PCS Per Month

- Port:

- Qingdao

Product Description

Alloy Permanent Mould Process Gravity Die Casting

We can supply Sand Casting, die casting, permanent mold casting, gravity casting, chill casting, low pressure casting .No matter what types of molding you need done, we're capability to do it perferlty with our factory or our cooperative partners. In our ranges, there are Four types of castings - aluminum sand casting, gravity die casting, Aluminum Die Casting and low pressure die casting. Our products are mainly automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, Valve parts, architectural parts and furniture parts.

2. Strict Quality Control

We can supply products with the following test reports:

1) Chemical composition report

2) Tensile strength report

3) Brinell hardness report

4) Metallographic structure report

5) Key dimension checking report

6) Full dimension report

7) Third part test report

We will design each speical checking tooling control key dimension during production to ensure each key dimension under control.

3. Packing:

A>Seger packing: Carton box+wooden case/pallet/iron cage

B>As pre client's special requirement

4. Our Service:

*A "bespoke" service to make castings and forgings to customers specific requirements with drawings, samples

*Market-oriented, different grades of products geared to the needs of different customers

*Advance equipment, professional technology and serious inspection procedure to ensure good quality

*In-time delivery will always satisfy customers" needs

*Best after-sale service all the time for a long trade cooperation term

5. FAQ:

Q1: What's the lead time?

A1: In general, the lead time is about 30~40 days for opening new moulds and mass production.

Q2: What file formats does Seger accept for drawings:

A2: The company ca accept a range of formats for drawings, but the main ones are detailed below: 2-D PDF AND TIFF 3-D STL, IGES, STEP, Solidworks, etc

Q3: Is it possible to visit seger to view it's manufacturing process?

A3: We are extremely proud of our facility and existing customers to visit our company. We think you will be impressed by us, as well as the warm welcome from our friendly, experienced team.

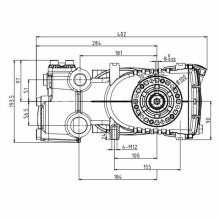

6. Specification:

Product Information | |

Material | A380 ,ADC-12, AlSi12, AlSi9Cu3 ,etc. |

Workmanship | Die Casting Gravity casting |

Surface Treatment | Shot blasting, Anodic oxidation, Painting, Sand blasting,Powder coating etc. |

Packing | Pallet, Carton, Wooden cases , etc. |

Certificate | ISO9001:2008 |

Standard | BS, JIS,GB, ANSI |

Application | Electric Vehicle |

Advantage | 1,High-speed production 2,Dimensional accuracy and stability 3,Harder and Lighter 4,Simplified assembly |

Product Categories : Die Casting&Gravity Casting > Die Casting Parts

Premium Related Products

Other Products

Hot Products

CE ISO9001 Certified Precision Metal Hook For Forklift PartCustom Drop Forged Steel Chain Links PartsSpiral Bevel Gear For Farm MachineryForging Trailer Axle Drop SpindleForging Fork Conveyor Link Chain Scraper ChainManufacturing Standard Trailer Parts 50 mm Trailer Ballcast iron rubber coated Hex DumbbellModel 3525 Auto Cars Water PumpHigh Quality Crank Forging/Forged Steel Shaft AxleGranulator Ring Die Pellet Mill Roll Shells,RollerHigh Quality Floating Animal Feed Pellet Production LineFactory Manufacturer Outlet Heavy Duty Trailer Drawbar Towing EyePrecision Zinc Aluminium Die-casting Productstainless steel pump impeller with investment castingOEM auto cast iron metal turbo exhaust manifoldHot Forging Parts Machining With 304 316 Stainless Steel