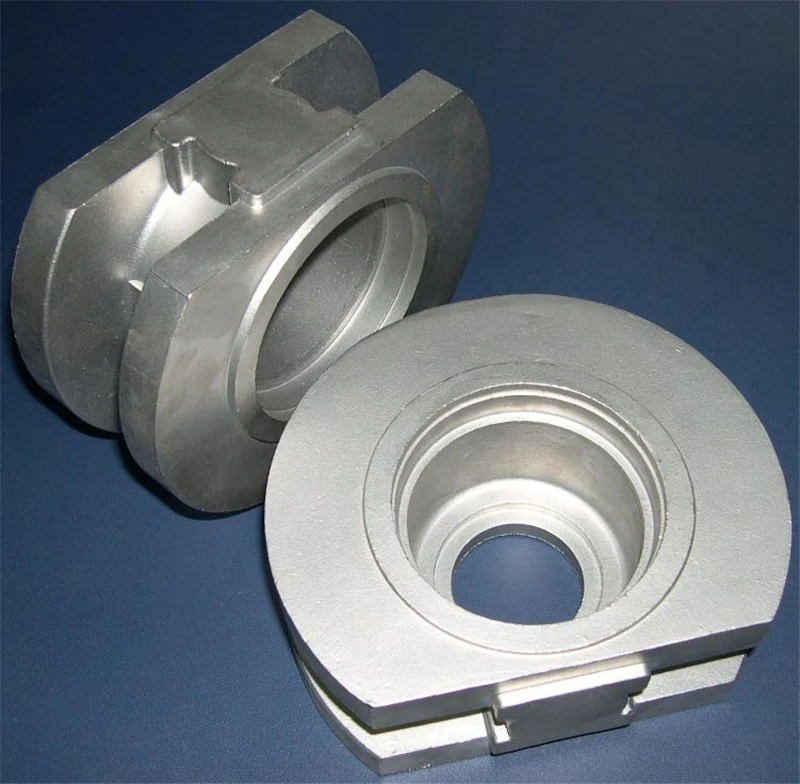

Industrial Casting Parts with Lost Wax Investment Casting

- Supply Ability:

- 100 Ton Each Month

- Port:

- Qingdao

Product Description

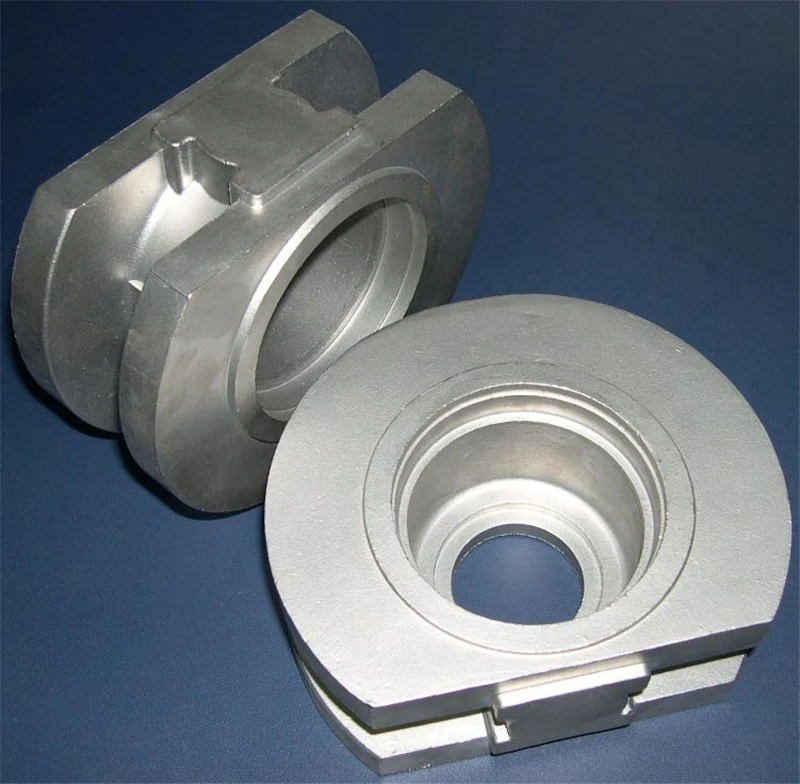

ISO 9001 Stainless Steel Investment Casting, Lost Wax Casting Manufacturer, SS304/316 precision Casting

We are skilled in investment casting, Materials vary from stainless steel, carbon steel, aluminium alloy, bronze, brass, and so on.

The application are for Hardware, Electronic Accessories, Machinery Parts, Agricultural Machinery Parts, Auto Parts, Furniture parts, Railway Parts, Drainage System and etc.

With a flexible mind focused on the existing needs, our objective is to provide products, services and solution that will enable our customers to become more competitive.

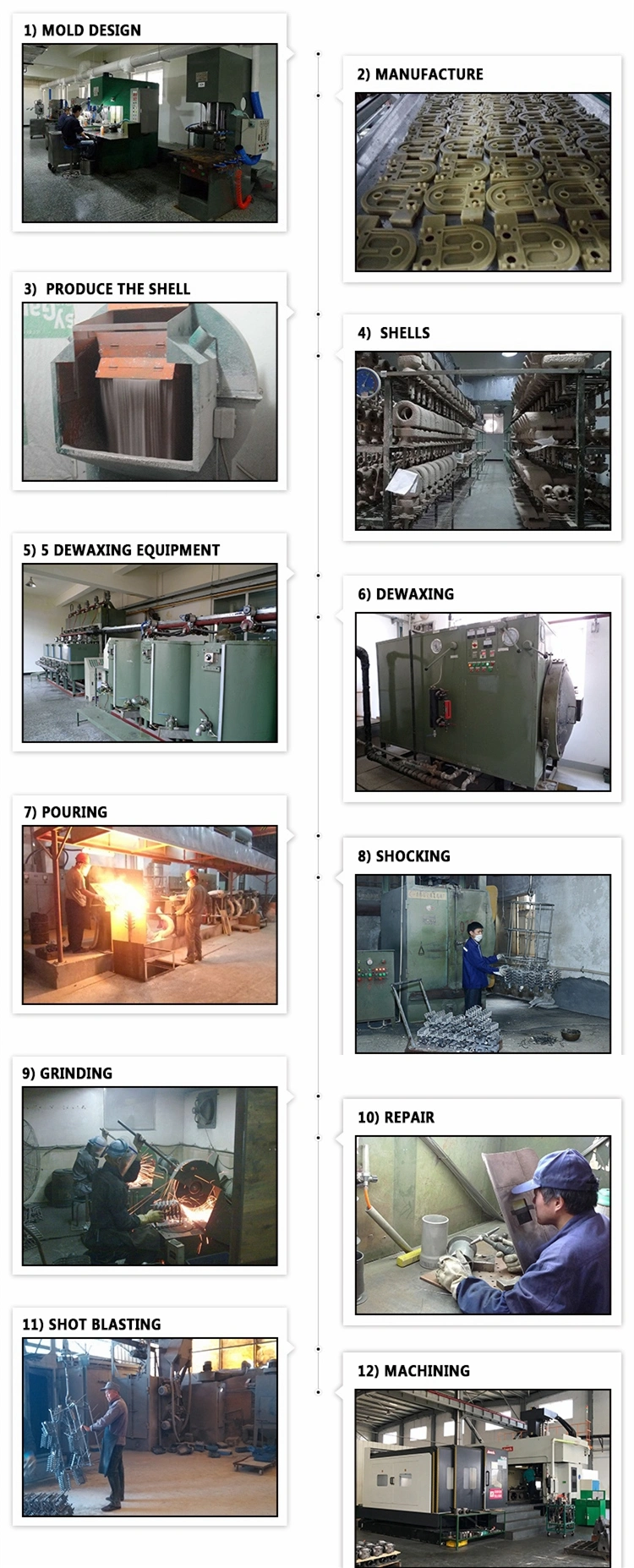

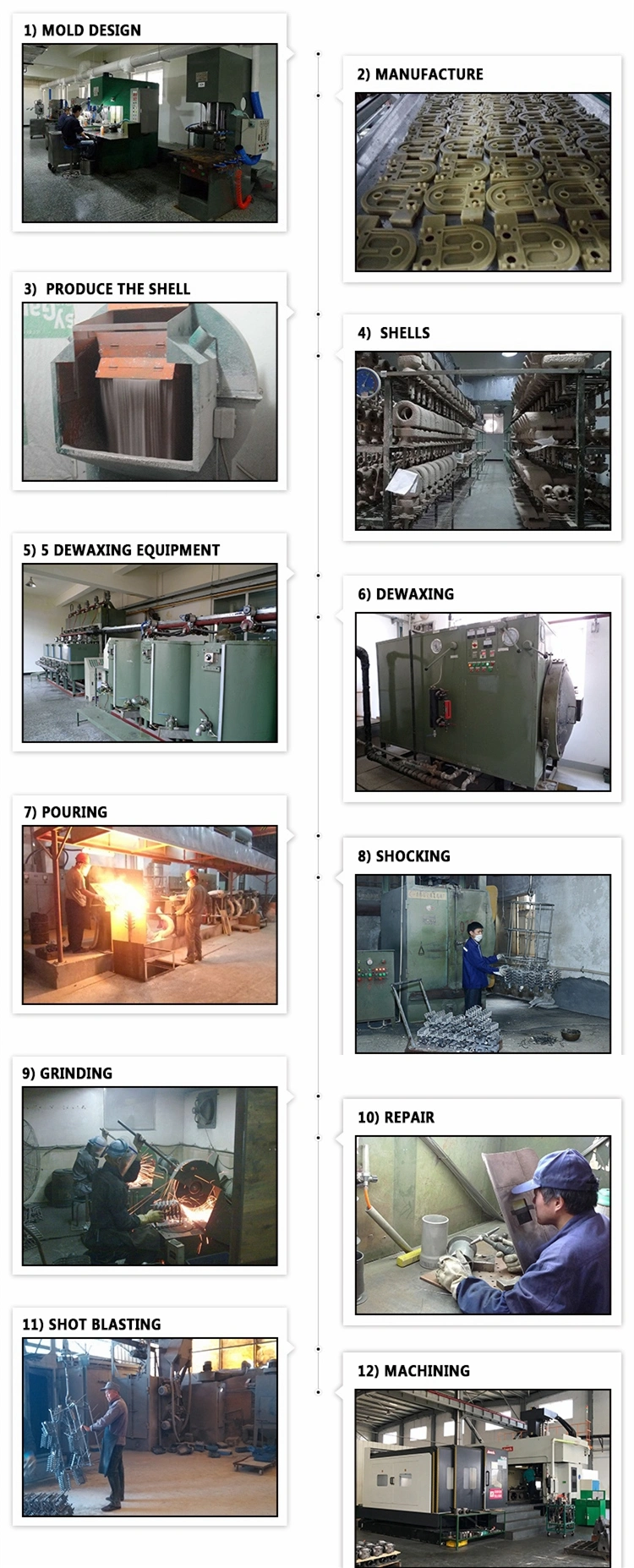

Process of lost wax investment casting

Production Information

Quality Control

Seger Industrial has built an excellent reputation for high quality in our industry.

The constant effort to improve service to customers has always been emphasized.

1. We check the composition of the raw material before purchasing and determine

whether the material comply with the specifications of the respective stainless

steel standards. For XRF analysis we use the INNOV-X DELTA DS2000

imported from USA, that help us to ensure quality from the beginning.

2. Test reports of tensile strength issued by third party are very important and helpful.

That could help our customers to choose the suitable size when these products

are used in particular cases.

3. Seger Industrial Stainless quality system conforms to ISO9001:2008,

we attain high quality products through monitoring production process

from material purchasing to receipt in warehouse.

Contact Information

Our Service:

Please submit as much of the below information as possible:

1. Pls provide complete 2D drawings of raw castings or finished parts, which should be clearly marked:

Part material, tolerances, heat treatment, surface treatment requiremnts; Point out the machining datum,

key dimensions tolerance & important surfaces that need to pay particular attention to.

2.3D drawings and samples are very necessary and helpfull for our quoting.

3. Testing and inspecting of the project & reporting requirements.

4. Order size and annual demand.

5. The requirements of process, packing and delivery.

6. FOB, CIF or EXW

Package

FAQ:

Q1: What are seger's current lead times?

A1: Our lead times are dependent upon casting and finishing requirements, but generally are as follow:

30days after receipt the down payment usually. Urgent need, please discuss with us to find a way out!

Q2: What file formats does Seger accept for drawings:

A2: The company ca accept a range of formats for drawings, but the main ones are detailed below:

2-D PDF AND TIFF 3-D STL, IGES, STEP, Solidworks, etc

Q3: Is it possible to visit seger to view it's manufacturing process?

A3: We are extremely proud of our facility and existing customers to visit our company.

We think you will be impressed by us, as well as the warm welcome from our friendly, experienced team.

Q4: When are seger's offices open?

A4: The company's offices are open from 8.30am to 5.30pm, Mondays to Fridays.

We are skilled in investment casting, Materials vary from stainless steel, carbon steel, aluminium alloy, bronze, brass, and so on.

The application are for Hardware, Electronic Accessories, Machinery Parts, Agricultural Machinery Parts, Auto Parts, Furniture parts, Railway Parts, Drainage System and etc.

With a flexible mind focused on the existing needs, our objective is to provide products, services and solution that will enable our customers to become more competitive.

Process of lost wax investment casting

Production Information

| Product name | ISO 9001 Stainless Steel Investment Casting, Lost Wax Casting Manufacturer, SS304/316 precision casting |

| Mainly Material | stainless steel, carbon steel, steel, aluminium, brass, bronze, copper |

| Process | investment casting, lost wax casting, silica sol casting. water glass casting |

| Casting tolerance | Lost wax casting -- CT4-CT6 (GB/T 6414) Water glass casting -- CT7-CT9 (GB/T 6414) |

| Standard | AISI, ANSI, ASTM, JIS, GB, ISO, DIN, |

| Certificate | SGS, ROHS, ISO, or as your requirement to do test by the third party |

| Machining | tapping, milling, grinding, drilling, cnc machining |

| Tolerance | +/-0.02mm or as drawing requirement |

| Surface treatment | polishing, electropolishing , mirror polishing, electrogalvanizing |

| Heat treatment | quchening and tempering, annealing, normalizing |

| Casting Roughness | Ra 3.2-Ra12.5 |

Quality Control

Seger Industrial has built an excellent reputation for high quality in our industry.

The constant effort to improve service to customers has always been emphasized.

1. We check the composition of the raw material before purchasing and determine

whether the material comply with the specifications of the respective stainless

steel standards. For XRF analysis we use the INNOV-X DELTA DS2000

imported from USA, that help us to ensure quality from the beginning.

2. Test reports of tensile strength issued by third party are very important and helpful.

That could help our customers to choose the suitable size when these products

are used in particular cases.

3. Seger Industrial Stainless quality system conforms to ISO9001:2008,

we attain high quality products through monitoring production process

from material purchasing to receipt in warehouse.

Contact Information

Our Service:

Please submit as much of the below information as possible:

1. Pls provide complete 2D drawings of raw castings or finished parts, which should be clearly marked:

Part material, tolerances, heat treatment, surface treatment requiremnts; Point out the machining datum,

key dimensions tolerance & important surfaces that need to pay particular attention to.

2.3D drawings and samples are very necessary and helpfull for our quoting.

3. Testing and inspecting of the project & reporting requirements.

4. Order size and annual demand.

5. The requirements of process, packing and delivery.

6. FOB, CIF or EXW

Package

FAQ:

Q1: What are seger's current lead times?

A1: Our lead times are dependent upon casting and finishing requirements, but generally are as follow:

30days after receipt the down payment usually. Urgent need, please discuss with us to find a way out!

Q2: What file formats does Seger accept for drawings:

A2: The company ca accept a range of formats for drawings, but the main ones are detailed below:

2-D PDF AND TIFF 3-D STL, IGES, STEP, Solidworks, etc

Q3: Is it possible to visit seger to view it's manufacturing process?

A3: We are extremely proud of our facility and existing customers to visit our company.

We think you will be impressed by us, as well as the warm welcome from our friendly, experienced team.

Q4: When are seger's offices open?

A4: The company's offices are open from 8.30am to 5.30pm, Mondays to Fridays.

Product Categories : Investment Casting

Premium Related Products

Other Products

Hot Products

CE ISO9001 Certified Precision Metal Hook For Forklift PartCustom Drop Forged Steel Chain Links PartsSpiral Bevel Gear For Farm MachineryForging Trailer Axle Drop SpindleForging Fork Conveyor Link Chain Scraper ChainManufacturing Standard Trailer Parts 50 mm Trailer Ballcast iron rubber coated Hex DumbbellModel 3525 Auto Cars Water PumpHigh Quality Crank Forging/Forged Steel Shaft AxleGranulator Ring Die Pellet Mill Roll Shells,RollerHigh Quality Floating Animal Feed Pellet Production LineFactory Manufacturer Outlet Heavy Duty Trailer Drawbar Towing EyePrecision Zinc Aluminium Die-casting Productstainless steel pump impeller with investment castingOEM auto cast iron metal turbo exhaust manifoldHot Forging Parts Machining With 304 316 Stainless Steel